22 Mar 2021

M+ A Masterpiece of Engineering and Design

A visionary new museum

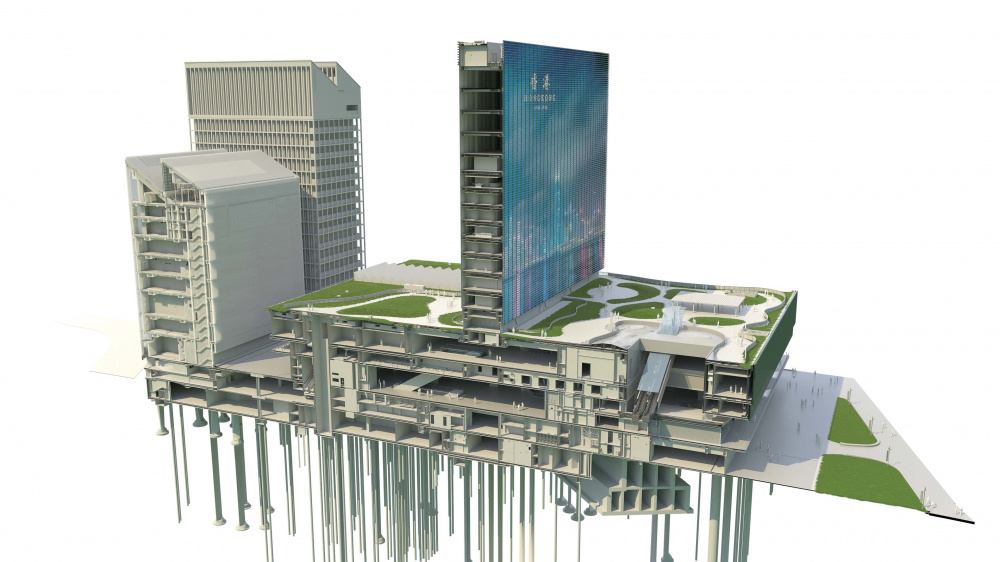

Designed by the renowned Swiss architectural firm, Herzog & de Meuron, M+ will change the world’s perception of Hong Kong by bringing together some of the world’s finest collections of visual art, design and architecture, moving images and Hong Kong visual culture in the museum’s 33 galleries, three cinemas, a Mediatheque, a Learning Hub, a Research Centre and other facilities.

The M+ construction project itself comprises the M+ building, the Conservation and Storage Facility, the WKCDA Tower with retail, dining and entertainment facilities and other arts and cultural facilities, an interfacing car park adjacent to the M+ building, and related public infrastructure works.

Even those without a special interest in the arts will be well served by the museum. In addition to the exhibition spaces, facilities will include a Roof Garden, two restaurants, a tea and coffee bar, and a members’ lounge, many of which will look out onto panoramic views of Victoria Harbour and Hong Kong Island’s urban skyline.

.jpg)

Trust and teamwork

One of the main challenges faced by Gammon was taking over the project following the company’s appointment as the management contractor in September 2018, well after construction of the superstructure of the museum building had started in 2015.

CC Hau, Executive Director at Gammon, said, “After our appointment, we had to help the team resume the project as soon as possible. As many of the trades people had been working on the site since the commencement of the project, it was important to gain their trust.

“Team building was essential, since about 150 members of the 300-member team were from outside Gammon,” said CC. “We assured them they would be treated fairly and worked hard to keep up their spirits.”

Another challenge was how to build over the tunnels of two existing live railways: MTR’s Airport Express and the Tung Chung Line. For the architects, this was an opportunity to create a unique “Found Space” for artists and curators staging large-scale art installations.

This was not an easy task, however, as the work had to be done within minimal tolerances – any disruption to the operating railway would have had disastrous consequences.

Fortunately, Gammon had experience working on the nearby Lyric Theatre Complex, which was also built over the Airport Express. Brian Gowran, Director at Gammon said, “All the issues we faced at M+ were the same as those we faced at the Lyric Theatre Complex. On that project, we were familiar with the operating regime.”

Another challenge faced by the team, like all of Hong Kong, was coping with the COVID-19 pandemic. During the early months of 2020, the outbreak of the virus caused lengthy delays in the progress of the works, as global supply chains shut down and deliveries fell behind by up to eight weeks.

According to K.W. Lee, Senior Construction Manager, “All we could do was to maintain contact with our suppliers and use DfMA to update the works schedule. It was totally beyond our control so we had to manage the best we could.”

Gammon’s technology advantage

Given the complexity of the project, Gammon made extensive use of advanced construction technology – one of the key strengths of the company – during the planning and implementation of the works.

Among the technologies deployed were Building Information Modelling (BIM), 3D Scanning, lasers, drones, IoT sensors and Augmented Reality (AR), all integrated under Gammon’s Integrated Digital Project Delivery (IDPD) approach for better planning, progress tracking and decision-making.

One area where these technologies came into play was the installation of the Mechanical, Electrical and Plumbing (MEP) services, which the client expected to be of a very high standard and completely hidden from view.

Concealing all the MEP services, including fibre optic cables, wiring, and fire service pipes, was a very difficult technical challenge. To help the engineers determine where the services would go, Gammon made use of Augmented Reality so they could visualise the desired locations precisely. Gammon's ability to use this technology, which provides substantial savings in time and money, was one of the reasons the company was selected for the project.

To protect these high value collections, Gammon helped to install an advanced long-throw sprinkler system for fire suppression. Additionally, environmentally friendly Novec 1230 gas will be used to ensure the museum’s artworks are not damaged by water in the event of a fire.

Lighting up the waterfront

One of the most memorable features of M+ will be the surface finish of the main tower, which is made up of precast concrete units incorporating terracotta tiles with a unitised aluminium facade behind.

The podium tiles of the facade, which resemble the bamboo tiles of Hong Kong’s distinctive Chinese roofs, were extruded in Italy and formed into precast concrete panels in China.

Ensuring these modules met the project’s quality standards was the responsibility of Paul Dymott, Senior Project Manager at Gammon. “The planning and sequencing of large units for delivery was critical,” he said. “Terracotta is long-lasting but also delicate, so great care had to be taken to bring them safely to Hong Kong.”

Delivering the units to Hong Kong and installing them on site required a great deal of coordination, which was made possible by using BIM for clash detection. The assembly of the units and their installation, as Paul points out, was also an example of the benefits of DfMA for achieving higher quality and savings in time, labour and cost.

What is perhaps an even more impressive feature of M+ is the giant LED system that covers the south facade of the tower. Measuring 110m in width and 65.8m in height, the system will be used for displaying moving images works. The panels making up the LED system were assembled in China, where they were tested and connected to the modular facade units.

Like all of his colleagues who worked on this project, Paul is tremendously proud of his contributions on this extraordinary museum that holds such significance for Hong Kong and the wider art community. As he puts it, “Some day, I will be able to look back on my career and say I’ve only done one museum … but it was a very special one.”

But even before then, everyone at Gammon can take great pride in this tremendous achievement of engineering that is bringing M+ towards completion and putting Hong Kong on the world cultural map.