The Gammon software robot that’s changing site reporting

Since 1999, we have held an annual innovation competition that is open to all staff, subcontractors and suppliers and which is judged by a panel comprising business partners, clients, stakeholders and management.

One of the finalists from 2017’s competition was Gambot™, a software robot with artificial intelligence (AI) that collects, stores and analyses site-related data, and it is having a profound effect on the efficiency of reporting on our projects.

Acting as a mobile virtual assistant, Gambot has an easy-to-use conversational interface and is predmoniantly used by staff at the frontline to improve safety and productivity on our sites. As an example, operational staff are submitting safety observations and dynamic risk assessments to Gambot through a messaging app that has guided questions, such as a request for a description and respective action items. The entire reporting process takes less than two minutes, a significant improvement over the traditional process.

Gambot is integrated with other IT systems such as Site Diary which collects site photos, i720 which focuses on quality checking, and our concrete management system. Understanding the context of image and video, Gambot also actively monitors if workers have entered pre-defined restricted or no-entry zones and generates an appropriate alert. Staff can even ask Gambot questions and get immediate answers.

Submissions are centralised and classified into different categories allowing management to strategically plan and monitor timely actions.

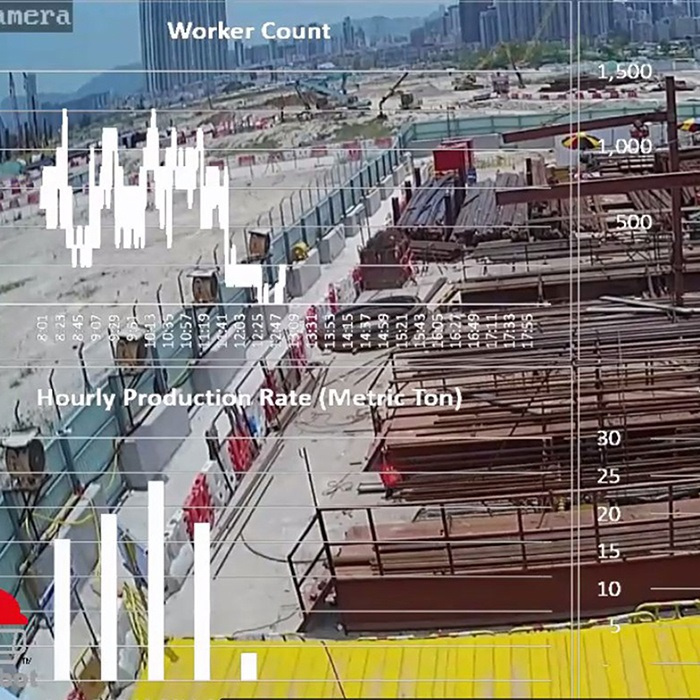

Gambot is the brainchild of a team of Gammon staff including engineers, project managers and IT who wanted to improve safety reporting on one of our high-rise projects. Now, all of Gammon’s projects submit safety observations and dynamic risk assessments through their invention, significantly improving the company’s safety management process and supporting a strong culture of Zero Harm. Recent updates to Gambot’s capabilities include computer vision that allows it to detect objects including workers, faces, vehicle plates, equipment and so on, allowing project teams to monitor productivity, or safeguard against entry to fatal or secured zones.

Bored pile scheduling can now also be carried out using AI powered software operating through Gambot